Petrof-DMAC - Waste Lube Oil (WLO) Recycling

Zero Clay Technology

Key Features

DE METALIZE + DE ASH + DE CARBON

DMAC is an indigenous PETROF technology for refining of used lube oil products. Some of its astute characteristics are:

- DMAC uses No Hazardous or Banned chemicals.

- DMAC removes Halogens,heavy metals, Sulfur and oxidized products and bring them withinpermissible limits.

- DMAC yields high quality base stock with better Color and Oxidation Stability with ZERO CLAY.

- DMAC Save Complete process Energy Consumption by 30%, as compared to other Processes.

- DMAC Prevents equipment fouling, corrosion, and coking ofprocess equipment such as heat exchangers and vacuum system.

- DMAC process separates bottom from feedstock which can be used as asphalt extender, rubber process oil, base for black printing ink, axle grease manufacturing and as rust proofing compound.

a. Final Product b. Oil after DMAC c. Waste Lube Oil

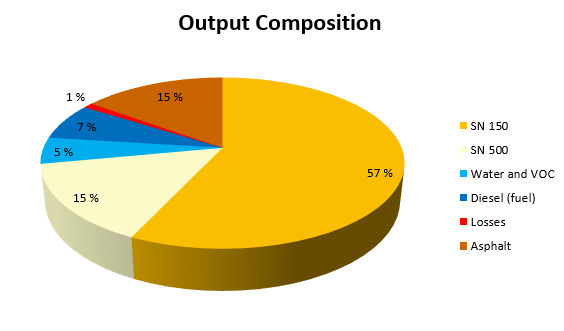

Output Composition