Crude Oil Refining Plants

Efficient yet thrifty

Introduction

PETROF – CRUOF is a efficient yet thrifty crude oil refining technology. CRUOF provides for customer satisfaction by touching many key aspects of refining. These are:

- Following our Just in Time principle, we make sure that our customers timing schedule is not disrupted in any manner. We primarily focus on acting swiftly and precisely to cater to your needs.

- We have a policy of Build, Operate and Handover. Thus, we leave no stone unturned to make sure that our clients face no glitches.

- Every single project of ours’ is personally handled by the best of our technical staff, excelling in their respective fields. Thus our systems are toned to perfection are Efficient to the core.

- We make sure that every project is packaged to perfectionin the best possible condition so that no damage is endured during freight.

- Any available International Standard may be followed as per the customer’s requirement.

PETROF – CRUOF Pros

CRUOF provides for customer satisfaction by touching many key aspects of refining. These are:

- Following our principle of Just in Time, we make sure that our customers timing schedule is not disrupted in any manner. We primarily focus on acting swiftly and precisely to cater to your needs.

- We have a policy of Build, Operate and Handover. Thus, we leave no stone unturned to make sure that our clients face no glitches.

- Every single project of ours’ is personally handled by the best of our technical staff, excelling in their respective fields. Thus our systems are toned to perfection are Efficient to the core.

- We make sure that every project is packaged in the best possible condition so that no damage is endured during freight.

- Any available International Standard may be followed as per the customer’s requirement.

The Process

Crude Oil Refining may be elaborated into the following steps:

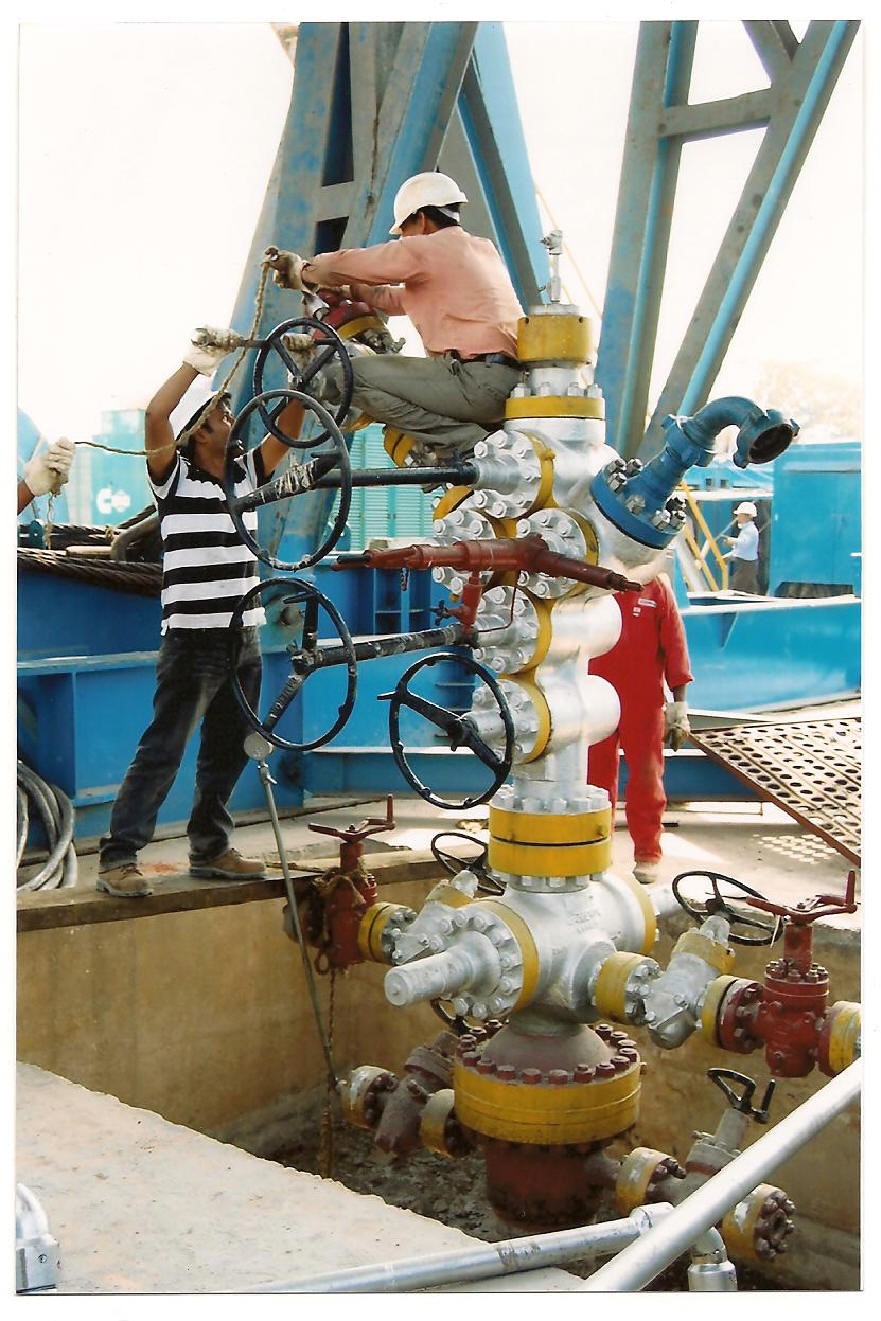

- The process begins with the extraction of crude oil. Foremost, to refine any crude oil, we must have some of it. Geologists and surveyors have their respective techniques (e.g. radar, sonar, etc) to determine and locate the earthly cavities which may contain accumulates of crude oil. These may be contained in subterranean locations or even in off shore, sub marine cavities.

- Next, these extracts are moved to a group gathering station where these are stored in a central storage facility.

- Preliminary separation of contents takes place in this step. The natural gas content is separated out, from which a bit may get condensed. This condensate consists mainly of volatile hydrocarbons and MS, MTT, SKO.

- The liquid crude part which has been separated is then stored in intermediate storage tanks and is ready for transport to the respective refinery. Depending upon the size of the consignment, the crude may be transported by rail or road. Rail transport obviously being for larger projects.

- Now, the crude is received at the refinery. After this the actually refining will take place. It is mostly by distillation. This distillation is performed in fractionating columns which may vary in size as per capacities. Further betterment of product may be brought about by catalytic cracking of higher hydrocarbons and blending the lower hydrocarbons with the respective cracked products.

- The distillation column is the real region of technology. Here various products of various differing boiling points will be obtained at their respective levels. The highest level is for the collection of the most volatile and lowest is for the heaviest & most viscous content. The intermediate levels are a gradual transmission. The number of these intermediate outputs are as per requirements